Bridging the gap between academia and industry, the new Touchdown Medical Technology complex at Cornell’s Tang Hall gives Meinig School Master of Engineering (M.Eng.) students the unique opportunity to engineer real-world solutions from concept to commercialization. Built over a decade with input from faculty, industry sponsors and students, the self-funded complex mirrors the pace, challenges and collaborative energy of professional medical technology development.

“Touchdown Medical Technologies is designed to simulate a startup company,” says M.Eng. program director and professor of practice Newton de Faria of the vision. “This structured yet realistic environment immerses students in the early stages of the medical technology innovation process, purposefully designed to deliver a rich, experiential learning opportunity that mirrors real-world entrepreneurial dynamics.”

The complex features dedicated spaces for every stage of the product lifecycle. The engineering studio and ideation rooms spark early-stage design, while the prototyping and specialized labs enable fabrication, testing and validation. The user experience suite captures clinical and end-user feedback, and the executive boardroom supports agile sprints, team evaluations and sponsor engagement. Together, these spaces give students a complete, hands-on view of turning ideas into market-ready solutions.

At the heart of this experience is a rigorous, educationally driven approach to project selection. Rather than working from predefined specifications or contractual obligations, de Faria, sponsors and students collaboratively choose projects based on their potential to teach the design process. The program emphasizes clearly defining problems and exploring solution pathways. But it doesn’t stop at the conceptual level — students engage in a comprehensive process of realizing and testing their ideas through iterative prototyping. They evaluate unmet needs, pitch viable solutions and assess the real-world functionality of their concepts.

Through this hands-on process, students develop critical thinking around product development, regulatory constraints and user experience. They also learn to identify and refine needs throughout the course of a design project, demonstrating real-world engineering judgment in action.

Recent projects include a generative AI tool designed to address communication gaps in nurse-patient interactions (sponsored by Baxter), a balloon-free, low-profile feeding device that offers a safer alternative for pediatric patients (sponsored by Boehringer Labs), new solutions in reconstructive surgery and a biodegradable anchoring cage for biologic implants to address spinal disc degeneration (sponsored by Weill Cornell Medicine). This last innovation won Cornell’s 360 Design Contest.

Thanks to the unique space and strategy defined by Touchdown Medical Technologies, Meinig School M.Eng. students gain hands-on experience that becomes a powerful asset during job interviews. Students can clearly articulate how they tackled real-world problems, iterated on solutions and collaborated with sponsors to identify the most effective path forward. Design projects play a fundamental role in helping students stand out by enabling them to tell a compelling, experience-driven story to share with prospective employers.

“In its entirety,” says de Faria proudly, “Touchdown Medical Technologies is more than a simulation – it’s a launchpad for future leaders in medical technology.”

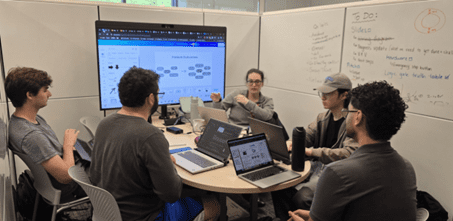

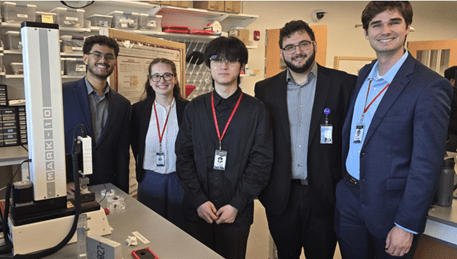

Undergraduate, M.Eng., and M.Eng.-M.D. students working in the design complex this past fall:

-

![Students using the meeting pods to apply the biodesign framework towards defining their “needs specification.”]()

Using the meeting pods to apply the biodesign framework towards defining their “needs specification.”

-

![Demonstrating their mechanical test set-up during the project showcase.]()

Students demonstrating their mechanical test set-up during the project showcase.

-

![]()

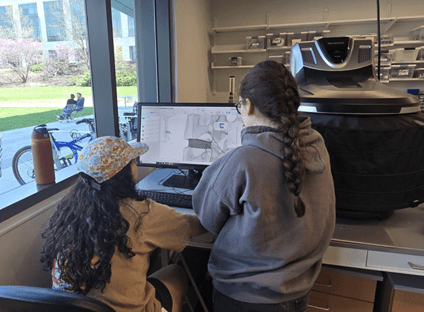

Working together to use the Keyance 3D microscope and CAD to develop intervertebral models.

-

![MEng student exploring the many different conceptual approaches towards the solution of identified and defined unmet need.]()

Exploring the many different conceptual approaches towards the solution of identified and defined unmet need.

-

![MEng students use their intracranial pressure simulation model to verify performance of their sensor in Tang Hall.]()

Using their intracranial pressure simulation model to verify performance of their sensor.

-

![MEng students working together in Tang Hall to model an infant pacifier to diagnose gastroesophageal reflux disease.]()

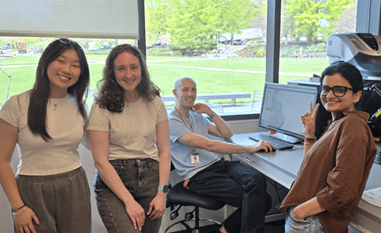

Working together to model an infant pacifier to diagnose gastroesophageal reflux disease.

-

![]()

Relax-while-working in the lounge/kitchenette.

-

![]()

Smiling at the soldering station.

link

More Stories

Stryker Expands R&D Facility in India to Boost Medtech Innovation

New leadership at e/MTIC: ‘collaborating even more’

Shaping the future of health through innovation and entrepreneurship | Waterloo News